Zhongtai is a specialized filling and packaging equipment manufacturer, located within Jintai Economic Development Zone of Jiangsu Province. Our factory spans across 5,550 square meters. Our packaging machines are installed in over 20 provinces in China, Southeast Asia, and more overseas markets.

We can supply packaging machinery for industries such as agrochemicals, chemicals, foods, and daily chemicals. All our packaging lines are computer program controlled and integrate optical, mechanical, electrical, sensing and pneumatic technologies.

Certificates and Honors

Through our efforts, we have earned ISO9001-2008 certificate and over 20 invention patents. All our products are CE certified. Additionally, we have become a member of China Light Industry Machinery Association, and achieved honorary tiles such as Top Ten Famous Brand in Seasoning Packaging Equipment Industry, Top 100 Small and Medium Sized Enterprise, etc.

Zhongtai Staff

We take pride in our expertise and innovative technical development team which is composed of 20 senior and junior technicians, as well as a group of skilled and experienced workers. We operate according to the principle of "satisfying and touching the heart of customers", and have created a complete production management system for quality assurance.

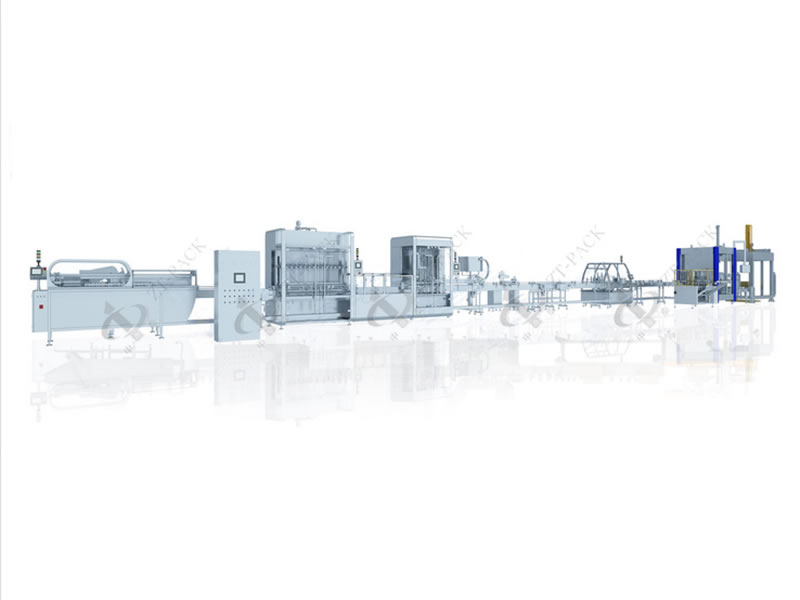

Packaging Line and Components Showcase

Backed by over a decade experience in our industry, we have developed a series of automatic packaging lines which are typically made up of the bottle unscrambling machine, filling machine, capping machine, labelling machine and sealing machine. Our bottling lines are intelligent, simple, stable, accurate, safe and eco-friendly.

Finished Products

Zhongtai packaging lines are classified into linear and rotary filling versions, and are compatible with round bottles, square and flat bottles, jars, pots, drums, and special shaped bottles as well with capacity from 25ml to 25L. Clients can choose a proper style of packaging machine according to the packaged product type, measuring method, material property, container shape, etc.

Incoming Material and Components Warehouse

We work with only qualified suppliers. In order to ensure the quality of raw materials, we have built a supplier management system, according to which we perform careful selection on candidate suppliers. Also, we perform strict quality control and inspection on incoming materials and components.

Production area for servo controlled packaging machines

The fully automatic servo controlled packaging machine is PLC controlled, and is designed on the basis of optical, mechanical, electrical, sensing and pneumatic technologies. Featuring high automation and accurate measuring, it is widely for packaging viscous fluids such as the vegetable oil, honey, fruit jam, syrup, pharmaceutical preparations, suspending agents, machine oil, and daily chemicals.

Production area for filling machines

Both linear and rotary filling machines are PLC controlled. Integrating optical, mechanical, electrical, sensing and pneumatic technologies, they offer fast and accurate filling, and features simple structure, convenient operation.

Production area for capping machine

Our capping machines also available in linear and rotary motion versions, and support automatic cap unscrambling, cap placing, cap screwing, and conveying.

The machine comes with simple structure and great stability, and can be custom designed according to bottle specifications. It is compatible with round bottles, flat and rectangular bottles as well as irregular shaped bottles for foods, medicines, cosmetics, daily chemicals, agrochemicals and chemicals.

Production area for labeling machines

We provide both self-adhesive labeling machines and wet glue labeling machines. Both types feature automatic bottle conveying, bottle grouping, guiding, photoelectric sensing, label delivering and labelling. They offer accurate and fast operation, commonly used for bottle labeling in industries such as food, pharmaceutical, daily chemicals, agrochemicals and chemical engineering.